DESCRIPTION OF

THE CONTINUOUS CASTING MACHINE (CCM) /

BILLET CASTER / CONCAST MACHINE / BLOOM CASTER / SLAB CASTER

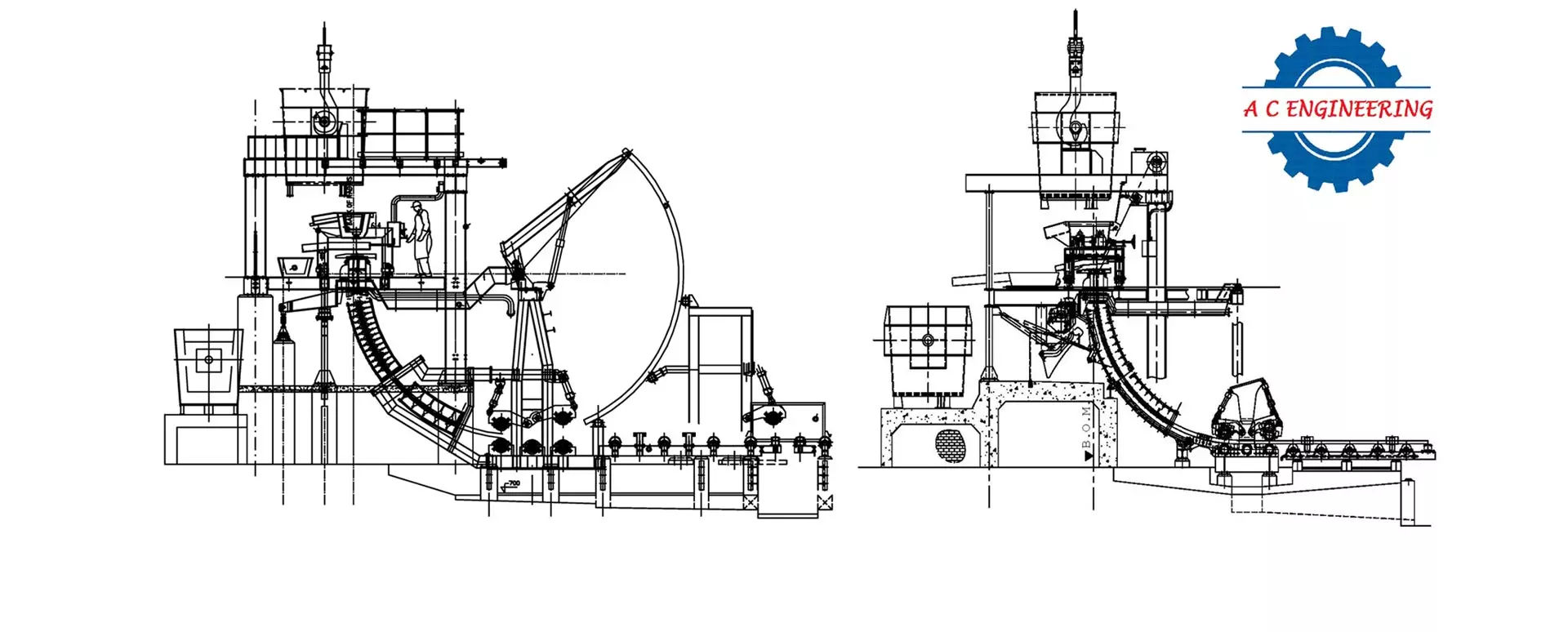

The Continuous Casting Machine / Billet Casting Machine / Concast Machine is an equipment to convert liquid steel into cast semis of the desired size.

Molten Steel from the furnace is poured at correct temperature into the Ladle and the Ladle Slide Gate is opened so as to allow the liquid metal to flow into the Tundish, which then allow it to the mould assembly through refractory nozzle. A tundish car is provided to transport the tundish to the Casting Station. Steel stream from the tundish is taken through the mould assembly which houses the curved copper mould tube to give the required shape of the section being cast. Read More ...

The main equipments of this machine are

- Ladle stand for holding the ladle in casting position

- Tundish (acts as a liquid steel distributor to strands)

- Tundish Car (for housing of tundish)

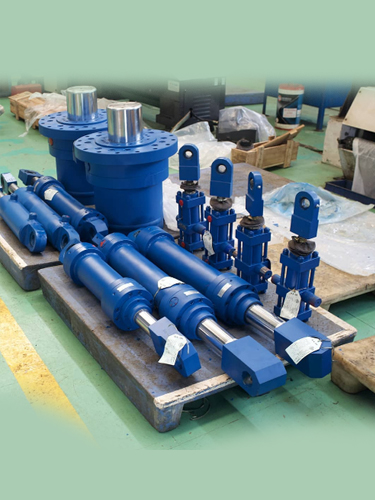

- Mould Jacket Assemblies

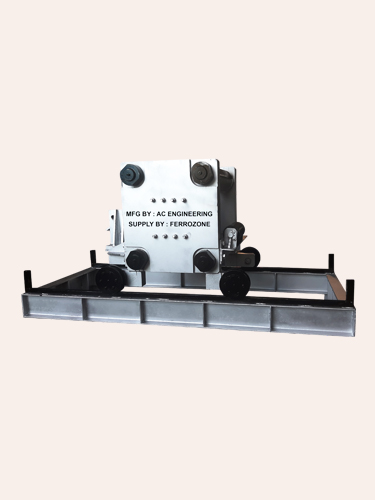

- Mould Oscillator

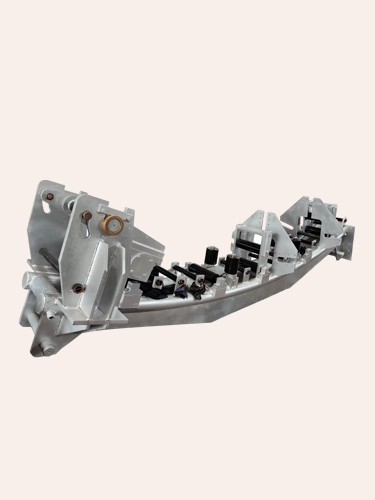

- Strand Guide frames

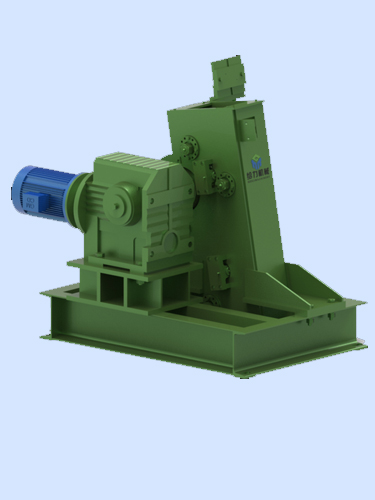

- Withdrawal-cum-straightening machine

- Electricals / Instrumentation etc.

Our Product Range